What is Six Sigma?

Know All About It

Six Sigma is a discipline of operations management and is focused on improving the overall quality of the operational activities, thereby enhancing the organizational performance as a whole. Following Six Sigma methodology allows organizations to achieve better customer satisfaction and higher profitability, by streamlining the operations, improving the overall quality and reduce the number of defects in each and every function and their respective activities across the firm. Thus, Six Sigma can be defined by:

‘A disciplined, data-driven, statistics-based approach and continuous quality improvement methodology aimed at eliminating defects in a product, service or process.’

Simplified by the PenMyPaper experts, it is a set of tools and techniques which has been designed to improve organizational performance by reducing the chance of error. This concept has originated from the statistical term sigma ‘σ’, which is a measure for standard deviation that is deviation from the mean value.

Six Sigma is one of the most critical subjects in the operations management domain and as a management student you need to have a complete and in-depth understanding of the core concepts. Our qualified essay writer can help clarify key concepts so that you have a better comprehension of this subject and don’t have to buy online essay.

The Six Sigma Process

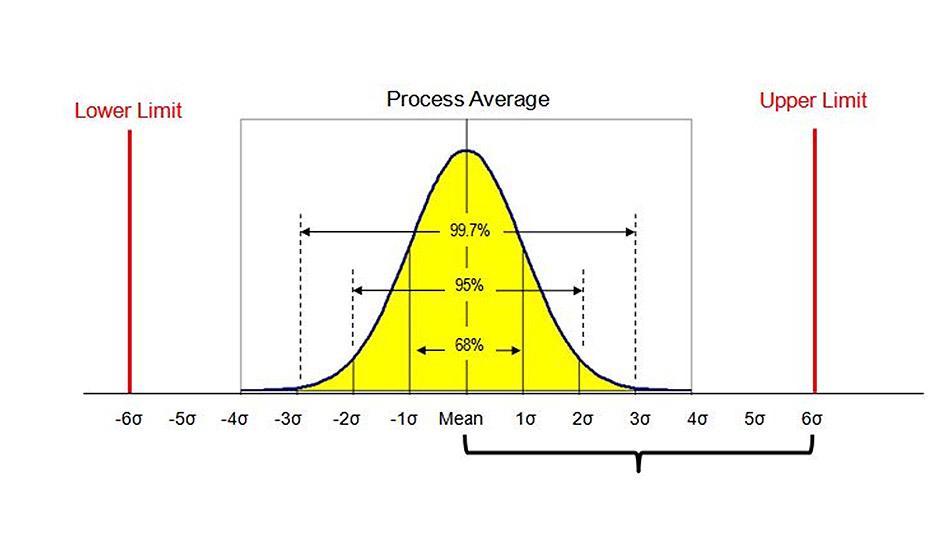

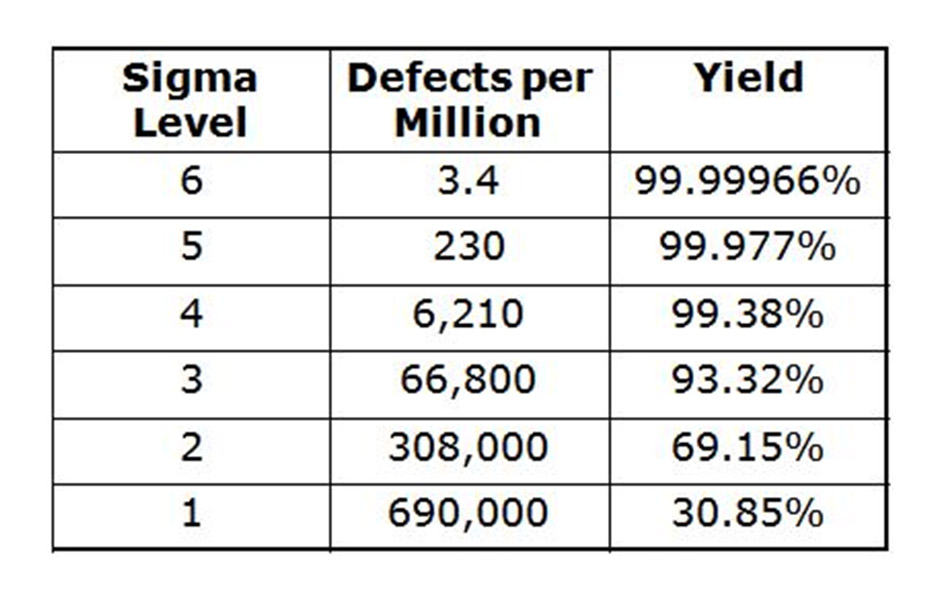

In order to have a clear understanding of what is Six Sigma, let us have a look at its process and how it works. As mentioned earlier, Six Sigma is a data driven approach to eliminating defects in operational processes. The sigma (σ) measures the variation in a set of data collected from an operational process. A defect can be defined in terms of its specification limits, which can be used to determine the process mean that is six units of standard deviation from the closest specification limit.

Thus, the Six Sigma process determines how an operational process should be reconfigured in order to stay as close as possible to the process mean. Ideally, with sigma level 6, the yield rate is close to 100 percent. Six Sigma allows organization to constantly improve quality by providing the best case yield scenario.

What is Six Sigma 5 Principles

The core purpose of Six Sigma is to deliver almost perfect goods and services which can improve business performance and lead to better customer satisfaction, which are crucial to long term success. This section covers the fundamental principles on which Six Sigma stands. As an operations management student, it is important for you to clearly understand each one of them and how they are related to each other. It can help you to finally prepare an APA format essay or even a quantitative research on Six Sigma.

The approach to Six Sigma can be discussed as a two step process, involving:

- Problem Identification

- Problem Solving

The identification of the problem is extremely crucial for the organization as it allows the manager to focus their efforts where it is needed. While identifying the problems, you need to ask: where does the activity deviate from and what it really should be? After determining the deviation, you also need to ask is the deviation significant enough to require any correction? You need to keep in mind that not every deviation needs correction, which is why the Six Sigma process helps to statistically determine the degree of deviation so that a more informed decision can be taken.

After the problem has been identified, it needs to be solved. It involves changing the state of the activity from what is it at present to what it really should be. This is the process which involves the quality improvement function, where managers actively take corrective measures to change the current activities to meet the required standards.

These two processes of Six Sigma are based on the foundations of 5 key principles, which are:

Customer Focus Approach

The primary objective is to generate maximum possible value for the customers, which is extremely crucial in driving business growth for the long term. In order to achieve the business plan on McDonalds vision statement that thrives to offer higher customer value, it is important to conduct a market analysis and understand their needs and preferences and to identify the factors which drives loyalty and fosters customer retention. Therefore, organizations need to define quality standards for their products and services, which can meet or exceed the expectations of the customer.

Accurate measurement of value stream and finding the problems

In order to meet the set quality standards, it is important to identify the problems in the operational processes so that they can be addressed. Managers need to have a clear idea about the all the activities in the process, so that they can ascertain which function generate value and which function do not. Such internal audit can help to visualize the workflow in the production or service delivery process in order to easily identify the bottlenecks and other issues which are restricting the full yield rate. Creating a value stream map is often useful in visualizing the concerned process in a form of a flowchart, thereby making it much easier to identify the root cause of the problem. In this case, it should be noted that identifying problems in a process can often become quite complicated, especially if there are a large number of issues present. In such cases, theoretical frameworks like the cause-effect diagram or the fishbone diagram can prove to be quite useful.

Eliminating variations to achieve continuous improvement and achieving efficiency

In order to improve the operational process, it is essential to remove wastes and non-value adding steps. However, in order to remove wastes, the organization must first define what is to be considered waste. As discussed previously while discussing the Six Sigma process, error or defects can be defined through a data driven approach, which can be quantified in terms of its upper and lower limit. Once the upper and lower limit has been defined then the process mean can be calculated by the Six Sigma methodology. Once the waste has been defined, it becomes much easier to identify and eliminate them. It should be considered while writing a thesis statement that the identification and elimination of waste is a continuous process, where an organization constantly seeks out to find new and hidden process bottlenecks and eliminate them as much as possible. This is why the Six Sigma method is considered to be a continuous quality improvement process.

Involving all stakeholders and cross-functional teams

Implementing the Six Sigma process brings significant organizational changes. As new defects and bottlenecks are identified and changed, it also changes the workflow of the employee. This as a result demands seamless and clear communication among all the stakeholders and cross-functional teams. Effective change management is a crucial part of implementing Six Sigma in an organization. All the stakeholders, including the employees need to be communicated about the imminent changes along with the purpose of such changes and how they can benefit them in the near future. While implementing the required changes, the entire process should be made accessible to the employees, especially the ones who are responsible for bringing the changes. Creating a process map can also help the employees to understand about the changes in their job roles and responsibilities.

Ensuring flexibility

Need to say that Six Sigma requires constant change within an organization. Since, it is a process of continuous quality improvement;therefore an organization needs to adopt a culture of flexibility and change. It is important for the managers to welcome new changes and encourage the employees to accept them as well. Moreover, maintaining flexibility within the organization also allows it to become highly reactive to market changes, thereby allowing the firm to effectively pacify adverse situations.

Understanding What is Six Sigma Too Tough for You?

Getting a complete grasp of what is Six Sigma can be quite overwhelming that’s why we recommend seeking help from a top quality essay writer. Understanding all the nuances of quality improvement using statistics-oriented decision making is not easy for a college student. Same in the case of writing about Amazon operations management. So, if you are stuck with your Six Sigma assignment and wondering who can writing my paper for me, simply hire our expert academics to help you out.